Optical Brightner, Sizing Agents, Wet/Dry Strength Resin

Optical Brightener for Paper (Find COA and Catalogue separately)

We all want our papers to be as white as possible, don't we? Well, that's where optical brightening agents come in. The raw material of paper often consists of impurities such as snippets of bamboo sticks and wood. These impurities dampen the brightness of the paper and that's why this sector creates a lot of opportunity for optical brightening agent manufacturers.

We have various Whitening Agent Optical Brightener Available for Paper application like…

| No. | Trade Name | Form | Type |

|---|---|---|---|

| 1 | BRIGHTOMNI BBU-P | POWDER | TETRA SULPHO |

| 2 | BRIGHTOMNI BBU-L | LIQUID | TETRA SULPHO |

| 3 | BRIGHTOMNI SFP-Z | LIQUID | HEXA SULPHO |

| 4 | BRIGHTOMNI ABP-X | POWDER | TETRA SULPHO |

| 5 | BRIGHTOMNI UP | LIQUID | DI-SULPHO |

| 6 | BRIGHTOMNI DSP | LIQUID | TETRA SULPHO |

| 7 | BRIGHTOMNI BMK | POWDER | DI-SULPHO |

| 8 | BRIGHTOMNI BMK-M | POWDER | DI-SULPHO |

| 9 | BRIGHTOMNI BBN CONC | POWDER | TETRA SULPHO |

Optical Brightener for Textile

Significant usage of the OBAs is in the textile industry where every cloth needs to be bleached before being processed as the raw material is full of impurities that come from pesticides, dust stuck to the fabric while transportation. And in fabrics sourced from animals impurities like animal fats, secretions, etc. need to be removed. However, bleaching doesn't offer complete whitening, which leads to the necessary usage of Optical Brightening Agents (OBAs).

We have various Whitening Agent Optical Brightener Available for Textile application like…

| No. | Trade Name | Form | Type |

|---|---|---|---|

| 1 | BRIGHTOMNI BBU-P | POWDER | TETRA SULPHO |

| 2 | BRIGHTOMNI AS Liquid | LIQUID | HEXA SULPHO |

| 3 | BRIGHTOMNI SI Liquid | LIQUID | TETRA SULPHO |

| 4 | BRIGHTOMNI 2B Powder | POWDER | TETRA SULPHO |

| 5 | BRIGHTOMNI BBN Conc | POWDER | TETRA SULPHO |

| 6 | BRIGHTOMNI TG Liquid | LIQUID | DI-SULPHO |

Optical Brightener OB DT for Detergent

Optical brightening agents (OBAs), also known as fluorescent brightening agents (FBAs), are chemical compounds that give whitening effect to Paper, Fabric, Detergent etc. They do this by absorbing light in the ultraviolet and violet region and re-emit the light in the blue region. This blue light reduces the yellow color of the substrate and give a brightened look. Unlike bleaching, it doesn't leave a yellowish thing and gives a much pleasing whiter-than-white appearance. Such a property sets optical brightening agents apart and makes it a much coveted thing in industries such as Textiles, Plastics, Paper, and Cosmetics.

Detergent Industry: The biggest requirement of OBAs is in whitening the clothes and therefore, it's no surprise that the detergent industry is the largest user of the fluorescent brighteners. As we all have experienced, clothes lose their natural whiteness over the course of time. That's where optical brighteners come in not just to protect that whiteness, but also to enhance it by converting low-density colors to the ones with higher density.

We have various Whitening Agent Optical Brightener Available for Ditergent application like…

| Detergent Optical Brightening Agent OBA 351 in powder form. |

| Detergent Optical Brightening Agent OBA 351 in Liquid form. |

| Detergent Optical Brightening Agent OBA 71 in powder form. |

| Detergent Optical Brightening Agent OBA 28 (A) in powder form. |

AKD Sizing Agent

Alkaline Sizing Agent. ALKYL KETENE DIMER (AKD) emulsion, designed to size the paper in the neutral to alkaline ph range of 6.5 to 8.5.

It is a free flowing white emulsion stable to size any type of furnishes preferably containing calcium carbonate.

Advantages of using AKD Sizing Agent.

- Easy size the paper at alkaline to neutral environment ( 6.5 to 8.5 ph)

- Effective at wide ph range

- Compatible with any filler

- Reduction in brightness reversion

- Increase brightness of paper

- Increase strength of paper.

We have various AKD SIZING AGENTS Available as under…

| Product Name | Solid Content | Form | Application | Packing |

|---|---|---|---|---|

| SOFTOMNI 1000 | 15-16% | Liquid | Paper | Barrel / IBC |

| SOFTOMNI 1000HS | 16-18% | Liquid | Paper | Barrel / IBC |

| SOFTOMNI 2000 | 18-20% | Liquid | Paper | Barrel / IBC |

| SOFTOMNI 2022 | 20-22% | Liquid | Paper | Barrel / IBC |

SAE Based Anionic Paper Surface Sizing Agent

Size press additives are present in the paper in full percentage. Mainly, the main aim of adding this material into the paper is to surge the overall strength, reducing dusting tendency, stiffness, and so on. Papermaking mills are also adding copolymers styrene maleic anhydride (SMA), styrene acrylates (SA), or urethane copolymers to size-press starch if they want to achieve increased resistance to liquids or higher levels of surface strength.

Actually, paper and board manufacturers use this product to improve the functional and visual applications of their products. And Omniscient International is there to help these companies to provide a wide variety of surface additives.

We try to cover the overall process of papermaking from printing to converting. This offers a unique presence in paper and board industry all around.

Keeping in minds the needs of the customers and high demand, we time to time discover new concepts by which paper efficiency, production, and demand surge

BONDOMNI 420 G with Solid Content 24 to 26 % (percentage) is our well result oriented product.

SAE Based Cationic paper surface sizing Agent

Omniscient International offers full range of sizing agents to help the paper making companies improve the aqueous holdout of their products. It greatly reduces the usage of inner sizing agents and can be used on paper machines for size press.

Omniscient International is one of the best organizations in improving surface properties of paper, side by side reduce the overall cost and increase the efficiency level.

Features

- It enhances the surface strength of paper/paperboard.

- It inhibits fuzzy printing caused by aqueous inks.

- It enhances the internal bond strength of coated paper (especially with low basis weight)

| Product Name | Total Solid (%) | Form | Application | Packing |

|---|---|---|---|---|

| SIZEOMNI 30 | 28-30 | Liquid | Paper | Barrel / IBC |

| SIZEOMNI 40S | 28-30 | Liquid | Paper | Barrel / IBC |

| CRAFTOMNI N100 | 24-26 | Liquid | Paper | Barrel / IBC |

Polyamido-polyamine-epichlorohydrin resin with a high% of solids 25-35% (Ionic charge- Cationic)

The most essential areas of wet strength resin are in the production of hygienic papers. They are inclusive of hand towels, cleaning clothes, facial tissue etc. Indeed, they are also used for toilets as they don’t block the sewage pipes.

Wet Strength Resin products are used in a variety of specialized papers such as paper-posters, labels, wallpapers, etc. that are required to retain a certain level of strength when moisturized.

Features

- With the help of wet strength resin, the target of productivity can be easily achieved

- It is so soft that machine starts running fast

- The overall quality of sheet improves like tensile strength, bulkiness, etc

- Saves a lot of energy while production

- Helps in the retention of sizing agent

| Product Name | Total Solid (%) | Form | Application | Packing |

|---|---|---|---|---|

| STRENGTHOMNI 6100 | 12-14% | Liquid | Paper | Barrel / IBC |

| STRENGTHOMNI 6200 | 18-20% | Liquid | Paper | Barrel / IBC |

| STRENGTHOMNI 6025 | 23-25% | Liquid | Paper | Barrel / IBC |

| STRENGTHOMNI 6033 | 30% +2 | Liquid | Paper | Barrel / IBC |

A Copolymer of Polyamide Dimethylamine with Epichlorohydrin.

Our product on the coagulant based on POLYAMINES used in paper / board mills. They may be used independently or supplemented with inorganic coagulants or with retention aids based on polyacrylamide.

Its promoters improve the electiveness of sizes, wet strength and dry strength resins and other additives in paper manufacture. These resins perform equally well on either cylinder or fourdrinier machines and in the presence or absence of alum.

Advantages

- Economical to use through low dosage requirements

- Effective over a wide pH range

- Wide molecular weight ranges available for specific applications

- Successful replacement or reduction of inorganic salts

- Ability to simplify delivery system through direct feed

- Immediately soluble at all concentrations

Benefits

- Fixing of sizing chemicals

- Good flock formation

- Improve Retention & drainage

- Effective trash control Improved clarity in white water

Economy

- Reduces use of sizing chemicals and alum

- Lowers addition of wet and dry strength resins

- Lowers filler cost through better retention

- More efficient use of dyes and pigments

- Lowers energy costs

- Fiber substitution potential

- Operation of machine at higher pH with less corrosion.

Reactive Dye

One of the most important components of the textile industry and many others, dyes are compounds that have the ability to adhere to any fabric leading to it being colored. There are a wide range of qualities as well as variants of dyes that are available in the market that manufacturers produce but the most preferred by users are those that color fabric at the soonest while being chemically stable. The two most important factors that qualitatively reflect any dye are temperature and time.

Being able to differentiate on the source from where they originate as well as how they can be applied, there is a wide range of dyes available. Dyes available through natural sources like plants or flowers are known as Natural Dyes as opposed to those that are not known as synthetic dyes. Similarly, there are dyes that can be differentiated on the basis of their application. One of the most popularly used variants based on its application is Reactive Dyes.

Reactive Dye is only class of dyes which makes co-valent bond with the fiber and becomes a part of it. This can be described as:

Reactive dyes + Fiber = Reactive dye + Fiber ( Co – Valent Bonding )

In reactive dyes, covalent bonds are formed with cellulose fibers. Such bonds give high fastness. It happens because strong bonds formed at molecular level are hard to break. Hence, they show better comparative durability against light and washing. There are lots of advantages of reactive dyes like

Advantages of Reactive Dyes:

- Owing to its ability to react with the medium gives a huge advantage to reactive dyes as they become much more long-lasting as well as visually distinct. This feature gives it a strong edge over prohibited colors as well as cellulose colors.

- Reactive Dyes have another strong advantage that is its wet speed, achieved through an efficient and straightforward coloring process.

- Reactive dyes are suitable for dyeing of a new type of cellulose Fibre products such as Lyocellfibres.

- Easy to Wash: The fibers that are dyed with reactive dyes can be safely dyed even with white garments without the danger of coloring it.

While there are many advantages of using reactive dyes, there are also a few disadvantages of reactive dyes like the environmental impact that reactive dyes cause among many others. But reactive dye manufacturers in India as well as across the world are investing a lot of efforts and resources in research that helps them develop products that are ecologically sensitive while delivering substantial and consistent value to the customers. Other challenges for this industry include finding skilled and talented workforce, government regulations as well as manufacturing costs. While the industry has a promising outlook, it is important that there is progress on the aforementioned fronts as well to avoid any hindrance.

Omniscient offers various reactive Dyes like…

| REACTIVE YELLOW 186 | REACTIVE BLUE 222 | REACTIVE ORANGE 16 | REACTIVE YELLOW 84 | REACTIVE BLUE 198 | REACTIVE RED 245 |

| REACTIVE YELLOW 145 | REACTIVE BLUE 223 | REACTIVE RED 198 | REACTIVE ORANGE 84 | REACTIVE YELLOW 95 | REACTIVE RED 218 |

| REACTIVE ORANGE 122 | REACTIVE BLUE 221 | REACTIVE RED 21 | REACTIVE RED 120 | REACTIVE YELLOW 18 | REACTIVE VIOLET 1 |

| REACTIVE RED 223 | REACTIVE YELLOW 42 | REACTIVE RED 111 | REACTIVE RED 141 | REACTIVE ORANGE 12 | REACTIVE VIOLET 13 |

| REACTIVE RED 194 | REACTIVE YELLOW 15 | REACTIVE RED 23 | REACTIVE GREEN 19 | REACTIVE ORANGE 13 | REACTIVE BLUE 13 |

| REACTIVE RED 195 | REACTIVE YELLOW 37 | REACTIVE RED 49 | REACTIVE BLUE 171 | REACTIVE ORANGE 35 | REACTIVE BLUE 49 |

| REACTIVE RED 250 | REACTIVE ORANGE 107 | REACTIVE YELLOW 135 | REACTIVE BLUE 89 | REACTIVE RED 24 | REACTIVE BLACK 8 |

| REACTIVE BLUE 194 | REACTIVE YELLOW 23 | REACTIVE YELLOW 105 | REACTIVE BLUE 160 | REACTIVE RED 45 | REACTIVE BLACK MIX |

| REACTIVE RED 11 | REACTIVE VIOLET 09 | REACTIVE BLUE 04 | REACTIVE BLUE 81 | REACTIVE BLACK 39 | REACTIVE BLACK MIX |

| REACTIVE YELLOW 86 | REACTIVE ORANGE 14 | REACTIVE YELLOW 14 | REACTIVE YELLOW 22 | REACTIVE ORANGE 4 | REACTIVE RED 2 |

| REACTIVE BLUE 25 | REACTIVE BLUE 21 | REACTIVE BLUE 71 | REACTIVE BLUE 72 | REACTIVE BLUE 5 | REACTIVE Yellow 77 |

Frequently Asked Question about Reactive Dyes:

1. What is Reactive Dye?

Ans: Reactive dye is chemically react with cellulost to form a covalent bond between dye molecule and cellulose.

2. Are reactive dyes eco-friendly?

Ans: If we considering uses of reactive dyes, then definitely reactive dyes are eco-friendly.

3. What’s the use covalent bonds in reactive dyes?

Ans: Colvalent bonds are use in reactive dyes to give high fastness.

Solvent Dye

We supplies and exports of a quality range of Industrial Dyes, which are available in various colors and shades. The range of products we offer include …

| Solvent Orange RL Dyes |

| Solvent Brown 2RM Dye |

| Solvent Green 33 Dye |

| Solvent Green Mix Dye |

| Black Solvent Dye |

| Lubricant Color |

| Solvent Dyes for Lubricant |

| Solvent based dyes for coloring gasoline |

| Solvent Red 89 Dye |

| Solvent Dyes Black 27 |

| Solvent Dyes Black 29 |

| Solvent Dyes Black 46 |

| Solvent Dyes Brown 45 |

| Solvent Dyes Brown 48 |

| Solvent Dyes Orange 58 |

| Solvent Dyes Red 49 |

| Solvent Dyes Red 89 |

| Solvent Dyes Red 119 |

| Solvent Dyes Red 122 |

| Solvent Dyes Red 127 |

| Solvent Dyes Yellow 82 |

| Solvent Dyes Yellow 90 |

| Solvent Green 3 Dye |

| Solvent Dye Violet |

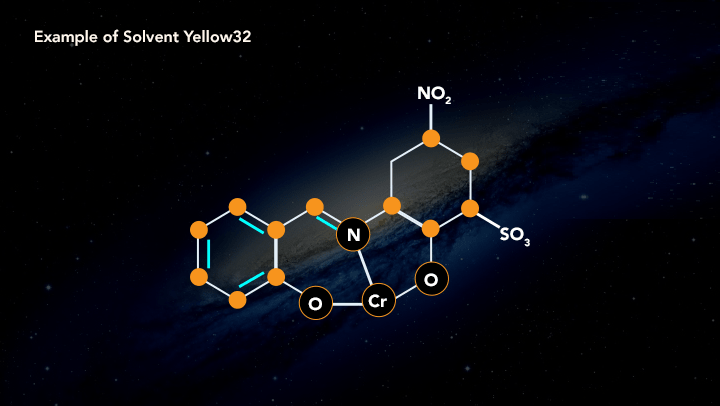

| Solvent Yellow 32 Dyes |

| And many more |

Solvent dyes are soluble in alcohol, chlorinated hydrocarbons and liquid ammonia but not water. These dyes show extensive use in petroleum industry. The colours of the dye is rendered by dissolving into target which are generally lipids or non-polar solvents. These are used to colour plastics, synthetics, gasoline, oil and waxes.

We stand out amongst the most noticeable supplier and exporters of prevalent quality Solvent Dyes to our customers over the globe. Our thorough scope of these colors is generally utilized as a part of different mechanical applications. These are accessible in different details and can be specially crafted according to the prerequisites of the customers. These are gotten to by our customers at aggressive costs in the business sector.

Features

- Accurate composition

- Easy to use

- Long shelf life

Synthetic Dye

All the dyes that are derived from organic and inorganic chemical compounds are synthetic dyes.

We offers wide range of Synthetic Dyes. These synthetic dyes can be named as per chemical structures of their particular chromophoric group. Some of the popular verities of synthetic dyes include:

- Diphenylmethane derivatives

- Triphenylmethane compounds

- Oxazine compounds

- Xanthine compounds

- Azo Dyes

- Acid Dyes

- Basic Dyes

- Chrome (or Mordant) Dyes

- Developed (or Diazo) Dyes

- Direct Dyes

- Disperse (or Acetate) Dyes

- Reactive (or Fiber-reactive) Dyes

- Sulphur Dyes

- Vat Dyes

Typical synthetic dye uses are in the field of textile, paint, and printing. The efforts of producing dye providing long-lasting coloring effect comes at the cost of highly stable organic structures and inert properties.

Synthetic Dyes offered by us are a first human-made organic dye that was discovered by William Henry Perkin in the year 1856. With thousands of synthetic dyes been prepared since then, Synthetic dyes are replacing traditional natural dyes as these are

- Cost less

- offered vast range of new colors

- Impact better properties to dyed materials

Today, dyes are classified as per how these are used in the dyeing process. With almost all colors seen being Synthetic dyes, these are used everywhere in everything right from:

- Clothes to paper

- Food to wood

- Impact better properties to dyed materials

Being used in 90% in dyeing units, these are versatile and simple to synthesize. Some of the parameters for choosing Synthetic Dyes include:

- Boiling

- Perspiration

- Fading

- Machine wash ability

- Gas fume fading (from oil heaters)

- Fastness assessments

- Dry cleaning

- Hot pressing

- Steam pressing

- Salt water

Applications of the Synthetic Dyes

Some of the most common applications these are used in include:

- Medicine

- Chemistry

- Plastics

- Paint

- Printing ink

- Rubber

- Rubber

Various Synthetic Dyes is there like….

- Synthetic Dyes for foodstuff

- Red Synthetic Dye

- Blue Synthetic Dye

- Yellow Synthetic Dye

- Green Synthetic Dye

- Acid Orange 7 Synthetic Dye

Natural Dye

Dying has been a flourishing trade since long, in different parts of the world. The dyes used in times before progress in chemical science were only natural. Dyes were derived from plants and animals. Indigo trade and farming in northern India is an example of the scale of trade.

Synthetic dyes have taken over the industry because of less cost and more reliability but natural dyes such as haematoxylin, carmine and orcein are still in use in the industry.

OMNISCIENT INTERNATIONAL offers a wide range of Natural Dyes for domestic, industrial and commercial like

| Barn Red Eco Natural Dyes |

| Natural Indigo Dye |

| Madder Roots (Turkey Red) DYE |

| Jaipur Pink Natural Dye |

| Jonquil Yellow Natural Dye |

| Mallow Gold Yellow Natural Dyes |

| Garnet Brown Natural Dyes |

| Cedar Yellow Natural Dyes |

| Michigan Brown Dyes |

| Apsara Yellow Natural Vegetable Dyes |

| Primrose Yellow Eco Color |

| Sun Yellow Natural Dye |

| Indigo Leaves Dye |

| Onion Peels |

| Eupatorium Natural Color |

| Silver Oak Natural Dye |

| Kamala Natural Dye |

| Wine Red Natural Color |

| Cuttack Silver Vegetable Dye |

| Crafty Brown Natural Dyes |

| Wisdom Orange Natural Vegetable Dye |

| Candy Orange Food Color |

| Gallnut Natural Dye |

| Henna Natural Hair Dye |

We are taking steps to serve the market demand considering significant factors like custom content and customer experience. The company is a leading dyestuffs supplier and exporter in India, and is striving to deliver the best quality of products to the customers, while being ecologically sensitive. OMNISCIENT is dedicated towards sustainable and safe development.

Disperse Dye

These dyes are relatively insoluble in water and were formed to dye secondary cellular acetate fibers. Disperse dyes are prepared by grinding of dye into fine particles and are dissolved in the solution with dispersing agents. Fiber absorbs the color upon submerging into the solution. Polyester, nylon, acetate and triacetate fibers are dyed using disperse dyes.

Backed by a team of adroit professionals, we are offering an extensive array of Multi color Disperse Dyes.

We, at Omniscient International aim to serve the disperse dyes industry with best quality product and service with competitive rates.

We are dealing with full range of disperse dyes and chemicals like…

| Powder Disperse Dyes |

| Black Disperse Dye |

| Red Disperse Dye |

| Disperse Yellow 3 Dye |

| Black Omniscient Disperse Dye |

| Omniscient Disperse Dye for polyester Dying |

| Blue Omniscient Disperse Dye |

| Disperse Blue 27 Dye |

| Disperse navy blue Dye |

| Disperse Red 4 Dye |

| DISPERSE YELLOW M7G DYE |

| DISPERSE ORANGE M2RL DYE |

| DISPERSE RED MBR DYE |

| DISPERSE RED MGF DYE |

| DISPERSE RED MGB DYE |

| DISPERSE BROWN MRH DYE |

| DISPERSE PINK MBF DYE |

| DISPERSE RUBINE M2B DYE |

| DISPERSE BLUE MGB DYE |

| DISPERSEBLUE M5R DYE |

| DISPERSE NAVY MGR DYE |

| DISPERSE BLACK MRD DYE |

Disperse dyes are our specialty and we can provide the customers' requirement in in customers' price range within customers' time frame.

We have a fully integrated supply chain of Disperse dyes and textile auxiliaries and one of the well known supplier of Disperse Dyes in India and overseas.

The offered products are processed using high-grade basic material and cutting-edge technology. These products are widely appreciated for supreme quality. The offered products are available in the different specification so as to fulfill the wide needs of the clients within the promised time frame. We have a customization facility also to cater to the exact need of customers. These products are admired by our clients for their excellent quality, fine colors, and effectiveness. Our transparent trade dealings have enabled us to establish a huge client base across the globe.

Direct Dyes

Direct dyes are applied to the fabric by preparing an aqueous solution and submerging the fabric in it. Fabrics which can form hydrogen bonds with the dye molecule are dyed with direct dyes. These became popular because the use of mordants or other binders became obsolete with this coming into use for cotton dying. Direct dyes provide better fastness than other dyes but lack color brilliance in comparison to other dyes. This is compensated by diazotization treatment. Fabrics such as cotton, linen, rayon, wool, silk, Jute and nylon are dyed with direct dyes. It is also use in plastic and rubber.

| DIRECT DYE COLORS | Solubility gm/I at 90 C | Fastness | |||

| Light | Washing | Perspiration (Alkaline) | Discharge Ability | ||

| violet 9 | 30 | 4 | 2 | 2-3 | 2 |

| Violet 51 | 40 | 5 | 3 | 2-3 | 2 |

| Brown NBMR | 50 | 4-5 | 3 | 2-3 | 3 |

| GREEN 2BNA | 50 | 4-5 | 3 | 3 | 3 |

| BLUE 86 | 50 | 6 | 3-4 | 1-2 | 2 |

| BLUE 1 | 50 | 5 | 3-4 | 2 | 2 |

| BLUE 15 | 45 | 5 | 3-4 | 1-2 | 2 |

| BLUE 54 | 40 | 4 | 3-4 | 1-2 | 2 |

| BLUE 71 | 45 | 5 | 3-4 | 3 | 5 |

| BLACK 80 | 70 | 5 | 4-5 | 3-4 | 4 |

| Black 22 | 20 | 4-5 | 3-4 | 3 | 3 |

| Black 51 | 50 | 5 | 4-5 | 3-4 | 3-4 |

| Black 155 | 50 | 5 | 4-5 | 3-4 | 4 |

| Black 165 BH NB Direct Dyes | 50 | 5 | 4-5 | 3-4 | 3-4 |

| Black 166 | 55 | 5 | 4-5 | 3-4 | 4 |

| Black 168 | 60 | 5 | 4-5 | 3-4 | 4 |

| Brilliant Yellow 4 | 60 | 04-Jan | 3-.4 | 3 | 3 |

| Yellow 44 5GLL Direct Dyes | 60 | 04/05/15 | 2 | 3 | 3 |

| Chrysophenine Yellow 12 G Direct Dyes | 40 | 3 | 03/04/15 | 02/03/15 | 4 |

| Direct Orange 26SE Dyes | 60 | 5 | 4 | 4 | 3 |

| Orange 39 TGLL Direct Dyes | 70 | 6 | 4 | 4 | 2 |

| Scarlet Red 23 4BS Direct Dyes | 70 | 3-4 | 3 | 4 | 3 |

| Red 31 12B Direct Dyes | 80 | 2 | 4 | 4 | 4 |

| Pink 80 F3B Direct Dyes | 75 | 5 | 3 | 4 | 4-5 |

| Red 81 5B Direct Dyes | 50 | 4 | 1 | 1 | 5 |

| Methyl Violet MB9 Direct Dyes | 30 | 4 | 2 | 2-3 | 2 |

| Helio B Violet 51 Direct Dye | 40 | 5 | 3 | 2-3 | 2 |

| Turquise Blue GL86 Dyes | 50 | 6 | 3-4 | 1-2 | 2 |

| Green 2BNA Direct Dyes | 50 | 4-5 | 3 | 3 | 3 |

| Sky Blue 1 FF Direct Dyes | 50 | 5 | 3-4 | 2 | 2 |

| Direct Blue NB 2B 54 Dye | 40 | 4 | 3-4 | 1-2 | 2 |

| Direct Black 80 NB Dyes | 70 | 5 | 4-5 | 3-4 | 4 |

Ultramarine Blue Pigments

We offer Industrial Grade Ultramarine Blue Pigment for textiles, Plastic masterbatches, plastic coloring, paints, cement paints, asbestoes and all industrial applications and coloring applications and whitening purposes. The range is widely used in diverse industrial sectors for a plethora. Our patrons can avail all our products according to their demands.

Features

- Skin and environment friendly

- Suitable for whitener on fabric, paper, plastics, rubber and paint

- Heat and alkali resistant

- Damp proof

- Reasonable price

Black Masterbatch

Omniscient International is the best masterbatch manufacturer, supplier, and exporter company in India. Also, we produce black, color and white masterbatches. Now, let's have look at each type and its features.

It's an important manufacturing material. Omniscient International deals with numerous black masterbatches. Even more, it is produced for PP, PET, ABS, PS, PE and many other polymers of the finest quality. There are many applications of it such as compounding, film extrusion, lamination, molding, woven sacks, fabrics, multi-layer, and mono-layer films, etc.

What makes us so special?

Most importantly, these are made with specially selected carbon blacks. It imparts characteristics like:

- Ultra Violet Protection

- High Jetness

For different applications, we have different black masterbatch. Ranging from general-purpose to premium black. Rather than our usual range. In addition, we accepts customized order according to the customer requirements. We provide the best cost-effective product to our customer.

Color Masterbatch

Omniscient International is committed to providing quality color masterbatch. It is a very essential element for industrial and manufacturing process. Our manufacturer and sales team are well qualified and experienced in providing the best product.

Just order and get the exact color match product delivered to you. We never fail in our promises. That's why we have achieved so high number of sales. Our product are designed in such a way that it qualifies all your requirements like applications, color, and quality. All perfectly matched and we are mainly focus on high quality.

The material or products produced in our factory are sent to many industries. We also hold close tie-ups with their various departments like in-house development. Whether compounding, film extrusion, lamination, molding or extrusion. Our product qualifies all boundaries to give you the best results, more than you expect.

White Masterbatch

We are well known for the supreme products supplier. Our team is perfectly experienced. These are produced using micronized Titanium Dioxide. Along with Titanium Dioxide, some specific polymers are appended according to different applications.

Hence, we produce different types of White Masterbatch for various applications. Some stabilizers and carrier resins are also included. It makes the final product better. Also, increases its sustainability.

Applications

- Compounding

- Film extrusion

- Lamination

- Molding

- Protective films

- Woven sacks

- FIBC bags

- Multi-layer films

- Mono-layer films

- Thermoforming

- and much more

Therefore, select the type of product according to your needs. Such as opacity, whiteness index, and dispersion. Furthermore, you can send an inquiry for customize order too.